coating thickness measurement methods|how to check plating thickness : agencies In the field of industrial ultrasonic testing, ultrasonic thickness measurement (UTM) is a method of performing non-destructive measurement (gauging) of the local thickness of a solid element . glass, ceramics, metal and other materials. Along with coating thickness, it is widely being used for thicknesses of glass, wood, and plastics and .

Watch Alisha Lehmann Muito Gostosa De Jeans video on xHamster, the greatest sex tube site with tons of free European Ass & Big Ass porn movies!

{plog:ftitle_list}

101 linhas · Find out the top 50 players with the most earnings from online tournaments in .

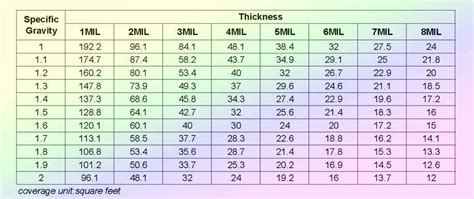

powder coating thickness chart

The ultrasonic pulse-echo technique of ultrasonic paint thickness gages (e.g. PosiTector 200) is used to measure the thickness of coatings on nonmetal substrates (plastic, wood, etc.) without damaging the coating.The other method to measure coating thickness, optical microscopy (Figure 17), is a destructive technique that exposed the edge of a coating under an optical microscope. The sample must be sectioned, then mounted and . In this blog post we'll discuss techniques and tools and learn how to measure thin film coating thickness. Search . 814-353-1778. Coatings & Services . Our Coatings . . XRF can be a relatively low cost method to . Appendix 6: Method for Measuring the Dry Film Thickness of Coatings on Edges. For decades, the industry was cautioned about taking coating thickness measurements within 1 inch of an edge, let alone on an .

ISO 3497 Metallic Coatings—Measurement of Coating Thickness—X-ray Spectrometric Methods 3. Terminology 3.1 Definitions of technical terms used in this test method may be found in Terminology E135. 4. Summary of Test Method 4.1 Excitation—The measurement of the thickness of coat-ings by X-ray spectrometric methods is based on the combinedIn the field of industrial ultrasonic testing, ultrasonic thickness measurement (UTM) is a method of performing non-destructive measurement (gauging) of the local thickness of a solid element . glass, ceramics, metal and other materials. Along with coating thickness, it is widely being used for thicknesses of glass, wood, and plastics and .Practice D 7378 describes three measurement methods for the thickness of applied, pre-cured coating powders to predict cured thickness. Test Method D 4138 describes destructive measurements over rigid substrates made with cross-sectioning instruments.

While standard paint and powder coating thickness measurement requirements can be accomplished using the magnetic induction or eddy current methods, some situations require a different technique. The phase-sensitive eddy current method is well suited for copper thickness measurement in PC board boreholes and surface copper thickness measurement .Coating Thickness. There are two methods for measuring the zinc coating thickness of hot-dip galvanized steel; a magnetic thickness gauge and optical microscopy. The simplest and non-destructive way is to utilize a magnetic thickness gauge, as optical microscopy is a destructive test only used to resolve measurement disputes. Overview of magnetic and eddy current measurement principles. When it comes to coating thickness measurement, two commonly used principles are magnetic induction and eddy current.Let’s take a closer look at each of these principles: 1️⃣ Magnetic Induction: Magnetic induction is a widely employed method for measuring coating thickness.It operates based . Coating thickness measurement on production line is a process to determine the thickness of a coating applied to a substrate. It is done to ensure that the coating is consistent, uniform and within specified thickness limits. The most common methods for coating thickness measurement are: – Non-destructive techniques: Magnetic induction; Eddy .

These specifications offer guidance on measuring the thickness of conformal coatings, whether the film is dry or wet. Typically, the coating thickness is determined based on the film material and the specific assembly function, following the recommended levels outlined in Table 1. Conformal Coating Thickness Measurement Methods Dry Measurement . A variety of recognized methods can be used to determine the thickness of organic coatings. The method employed in a specific situation is most often determined by the type of coating and substrate, the thickness range of the coating, the size and shape of the part, and economics. Commonly used measuring techniques are nondestructive dry film methods such .Example A: Imagine you take a measurement on a steel coil coated with zinc galvanize using a PosiTector 6000 F gage and obtain a single-side thickness reading of “0.35 mils.”This can be easily converted to oz/ft² using the following method: Multiply the gage reading of 0.35 mils by 2 to account for both sides of the panel (0.70 mils)

A modular measurement system that automatically measures coating thickness and conductivity improves inline quality assurance processes by identifying even the smallest deviations in production. Five different modules allow for the use of all the common electromagnetic measurement methods.For non-destructive coating thickness measurement on iron and steel, i.e. ferro-magnetic substrates, the magnetic-inductive principle is used. . All Surfix® models meet special international standards for thickness measurement: .

In order to explore the effective method for coatings thickness inspection, ANSYS numerical analysis method is used to establish a three-dimensional finite element heat transfer model as shown in Fig. 3.The substrate has a dimension of 300 mm (length) × 10 mm (width) × 5 mm (height).On top of the substrate (red color 1), the graded coatings (green color) is .

The measuring method introduced provides a user-friendly and reliable means of nondestructive thickness measurement for duplex coating systems on steel and iron that may consist of a zinc coating with a paint or plastic coating applied on top of it.

The other method to measure coating thickness is a destructive technique that exposes the edge of a coating under an optical microscope. The sample must be sectioned then mounted and polished to show the exposed edge of the hot-dip galvanized coating. The calibrated eyepiece of an optical microscope can then determine the thickness of the coating.

The eddy-current method of coating thickness measurement measures non-conductive coatings on non-ferrous conductive substrates, non-ferrous conductive coatings on non-conductive substrates and some non-ferrous metal coatings on non-ferrous metals. It is very similar to the magnetic induction method and can even use many of the same probe designs. In 2007, Yasuda et al. [31] proposed a numerical fitting-based thickness measurement method using multiple regression analysis and least squares fitting to achieve the thickness measurement of paint coatings, but the method was limited by the model accuracy and the limitation of linear estimation.Appendix 6: Method for Measuring the Dry Film Thickness of Coatings on Edges. For decades, the industry was cautioned about taking coating thickness measurements within one inch of an edge, let alone on an edge.Measurement of coating thickness — Magnetic method 1 Scope This International Standard specifies a method for non-destructive measurements of the thickness of non-magnetizable coatings on magnetizable base metals. The measurements are tactile and non-destructive on typical coatings. The probe or an instrument with

Metallic and oxide coatings — Measurement of coating thickness — Microscopical method 1 Scope This International Standard describes a method for the measurement of the local thickness of metallic coatings, oxide layers, and porcelain or vitreous enamel coatings, by the microscopical examination of cross-sections using an optical microscope.

measuring paint thickness on metal

This paper reviews earlier studies focusing on thickness measurements of thin films less than one micrometer thick. Thin films are a widely used structure in high-tech industries such as the semiconductor, display, and secondary battery industries. Typical non-destructive and non-contact techniques for measuring the thickness of thin films are spectral reflectometry . The production of barrier packaging materials, e.g., for food, by physical vapor deposition (PVD) of inorganic coatings such as aluminum on polymer substrates is an established and well understood functionalization technique today. In order to achieve a sufficient barrier against gases, a coating thickness of approximately 40 nm aluminum is necessary. .

The correct conductive measuring system depends on a variety of factors, such as the coating type and material type. But one commonly suggested method for conductive thickness coating is a modular measurement system (MMS). A modular system automates the measurements on conductivity and thickness, in addition to the substrate material. The thickness of the thermal barrier coating (TBC) has an important impact on the thermal insulation performance and in-service life. The TBC consists of multiple coatings layers in which the metallic bond coat has similar characteristics to the alloy substrate, and therefore, most thickness measurement techniques are difficult to measure the thickness of the metallic .

test results of bottled water

Grupo de Telegram Sinais mines Realsbet da categoria Links para você entrar e participar! Acesse milhares de grupos, canais e bots de Telegram, clique e confira! Home. Categorias. Enviar. Meus Envios. Sinais mines Realsbet. Seja bem vindo ao bot do mines Primeiro de tudo você deve se cadastrar na casa que estamos conectados. Aqui está o .

coating thickness measurement methods|how to check plating thickness